Our turning technology specialists have access to all the top technologies the market has to offer. CNC-controlled single and multi-spindle machining centres, as well as conventional machine tools, high-performance induction hardening systems, various grinding machines and a system for automated component assembly, enable us to carry out a wide range of process steps in-house. In addition, the technological advantage guarantees that we can make reliable delivery forecasts and always keep an eye on the component quality.

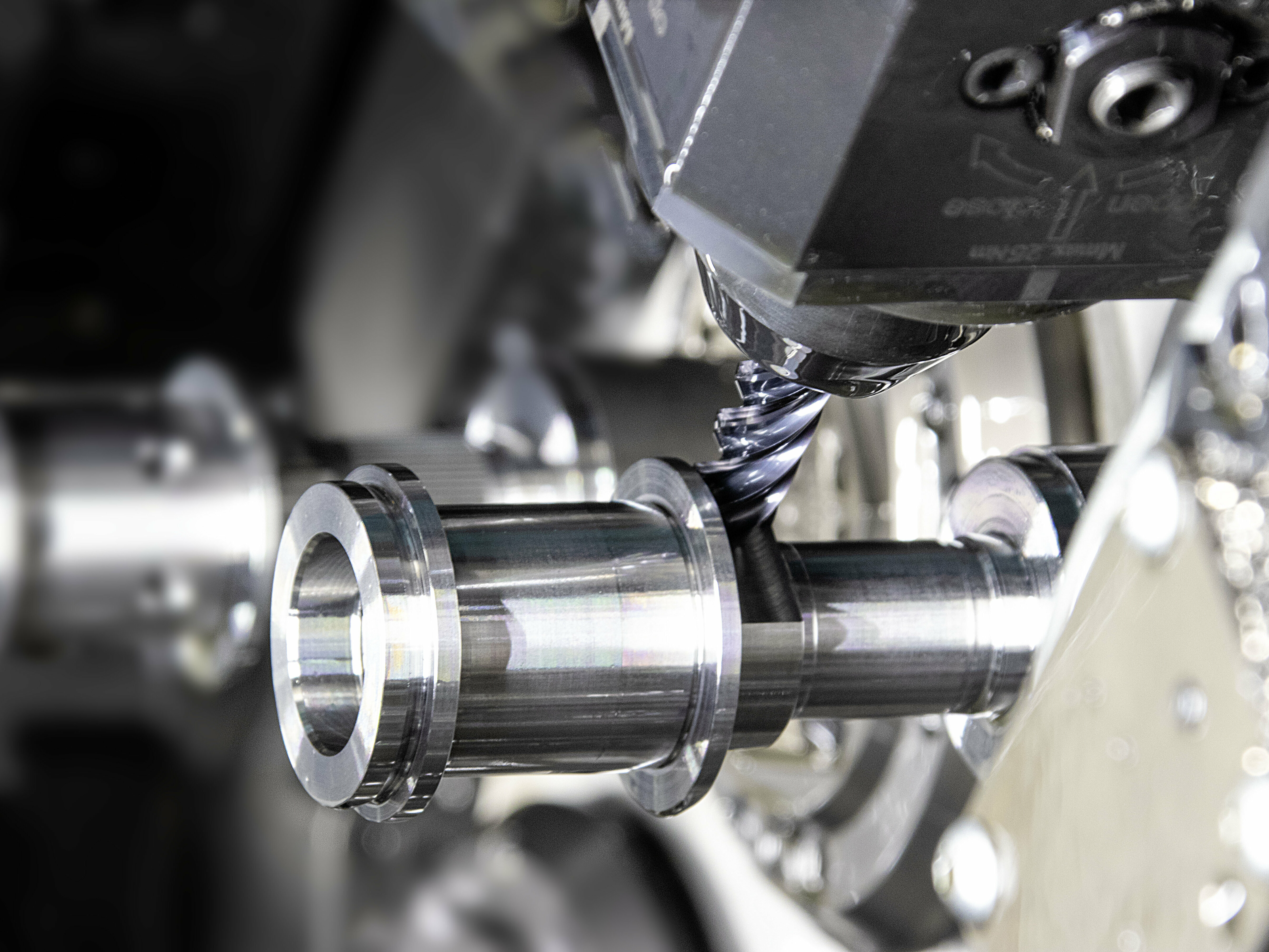

TURNING

We reliably manufacture precision turned parts on state-of-the-art machinery. The combination of different manufacturing technologies is the guarantee for the cost-optimised production of your products.

We process steel, stainless steel, aluminium, brass and all other machinable materials in the diameter range from 5 to 250 mm in a wide range of batch sizes and up to large-scale production.

Milling operations can be implemented as part of the turning process and thus offer the possibility of producing complex parts.

HARDENING

Our induction hardening systems enable us to partially harden workpieces directly after production. The integration of this technology into our production makes it possible to coordinate dimensions between production and hardening shop in the shortest possible time.

All other heat treatment processes – such as plasma nitriding, case hardening, quenching and tempering or nitriding – are reliably carried out by our regional, certified cooperation partners.

GRINDING

State-of-the-art CNC external cylindrical high-speed grinding machines enable us to produce high-precision external diameters with the corresponding surface finishes.

Other grinding processes – such as external or internal cylindrical grinding in through-feed or plunge-cut processes, but also the grinding of grooves – are carried out by certified service providers.

ASSEMBLY

From workstation assembly, to the joining of workpieces, to the automated assembly of components, we have the right process for our customers’ requirements.

100% INSPECTION

To ensure the highest possible delivery quality, we are able to subject our products to a 100% inspection by means of part-specific sorting systems and video measuring devices.

By using our extensive measuring technology in air-conditioned measuring rooms and the constant qualification of our employees, we ensure the permanently high quality of our production. Initial sampling prior to the start of series production or the collection of measurement data during production and its statistical analysis are all part of the process

Evaluations are the building blocks of our quality policy. We are certified according to IATF 16949.

LICENCE TO... TURN.

Like in a perfectly organised clockwork, one cog meshes with the other at MEYER Drehtechnik GmbH: Our highly effective quality management approach is certified according to IATF 16949 and exceeds the usual standards of the automotive industry. Intensive staff training, precise work instructions and highly motivated employees ensure quality work at the highest level. Our 3D measuring laboratory, equipped with the latest precision measuring technology, underlines this claim to delivering the best quality.

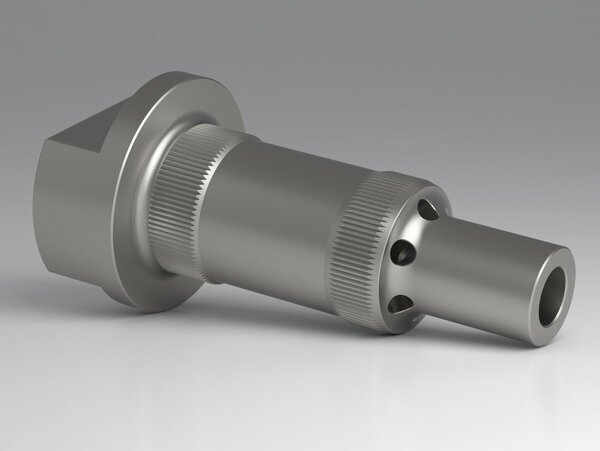

DRIVE PLUG

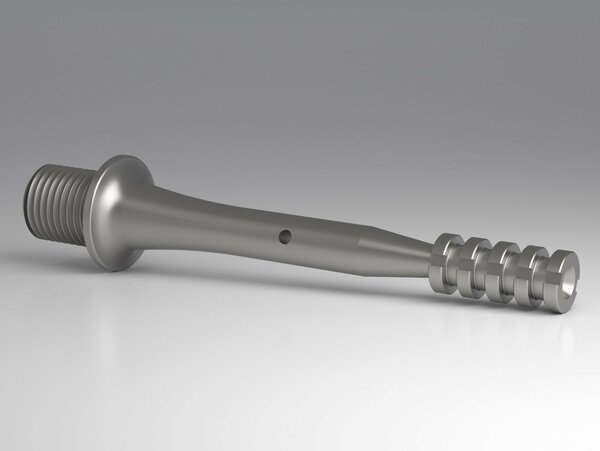

ADJUSTING SCREW

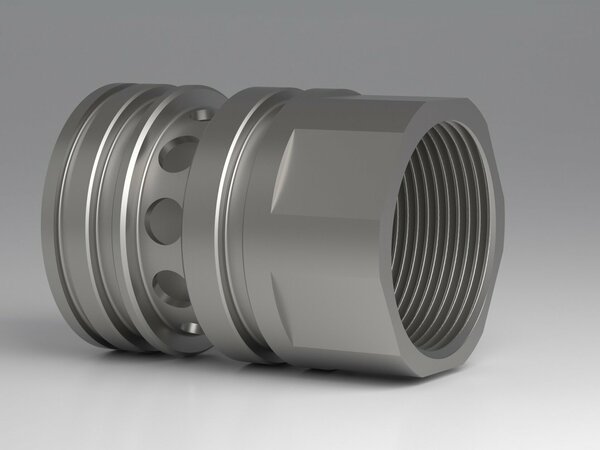

CYLINDER

PISTON

REGULATOR

FITTING

END PIECE

COUPLING SHAFT

CONNECTOR

CONTROL UNIT